Foam polyethylene with close cell

Closed cell polyethylene foam is the most common among plastics, it is a closed cell material, its main characteristics are: lightness, elasticity, excellent shock and vibration absorption capacity, good performance as thermal and acoustic insulation.

It is also floating, resistant to water and atmospheric agents. There are different types that differ in density, cell size, elasticity, rigidity, etc. which make closed cell polyethylene foam suitable for use in different application areas.

Some types of foam polyethylene at close cells which POLIPLAST treats by way of example but not limited to are:

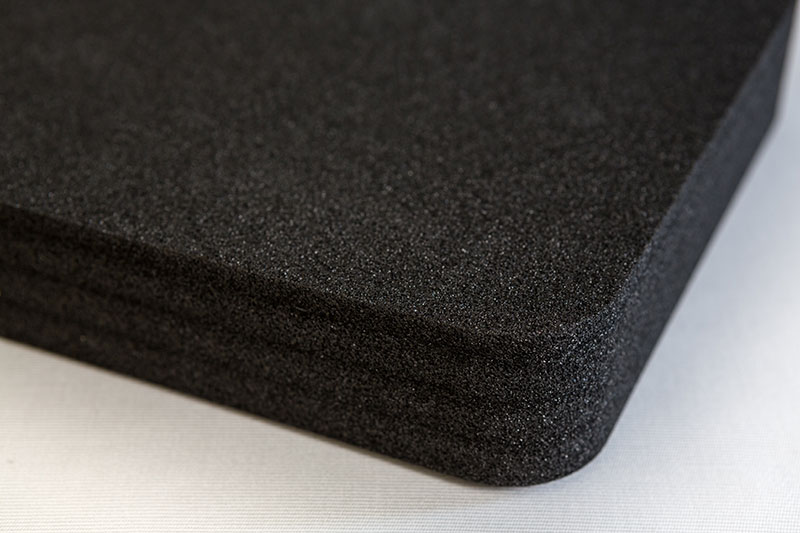

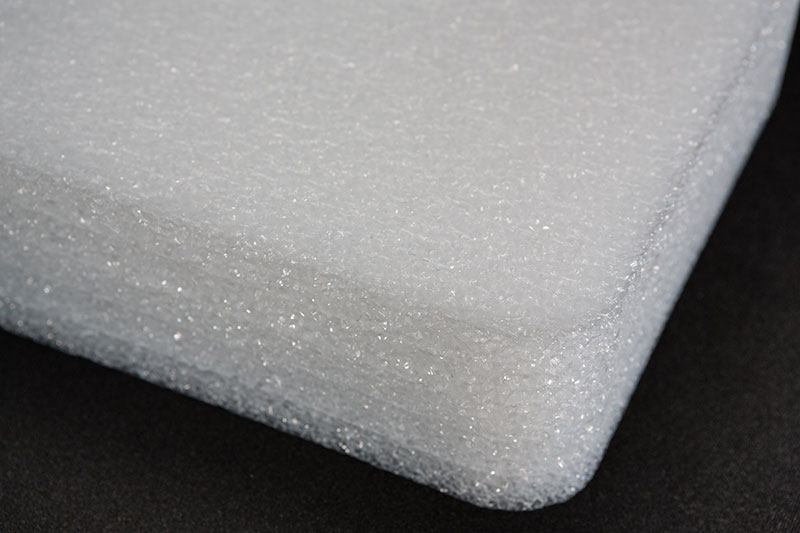

STRATOCELL

Extruded polyethylene foam, light and elastic with high impact resistance, particularly suitable for impact-proof protective packaging and for the creation of cases and layers for internal handling. It is also floating and water resistant. Also available in pink antistatic version for the packaging of electronic components. It comes in both sheets and rolls of different sizes and thicknesses.

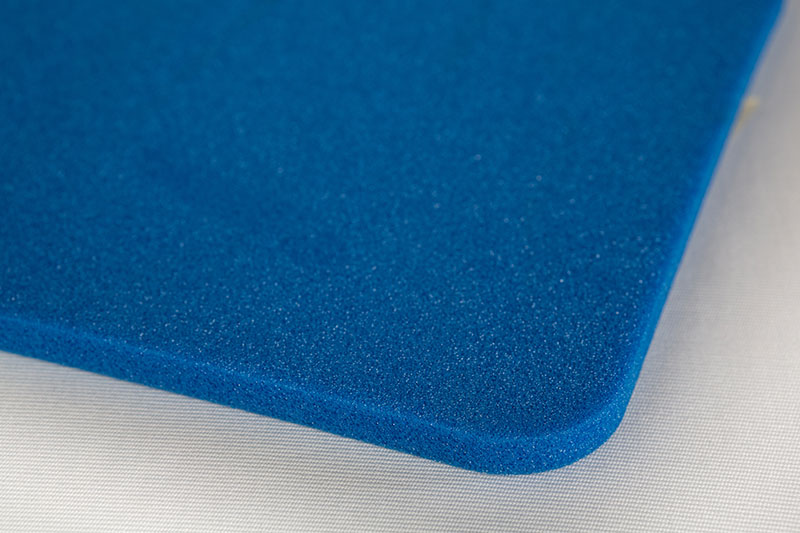

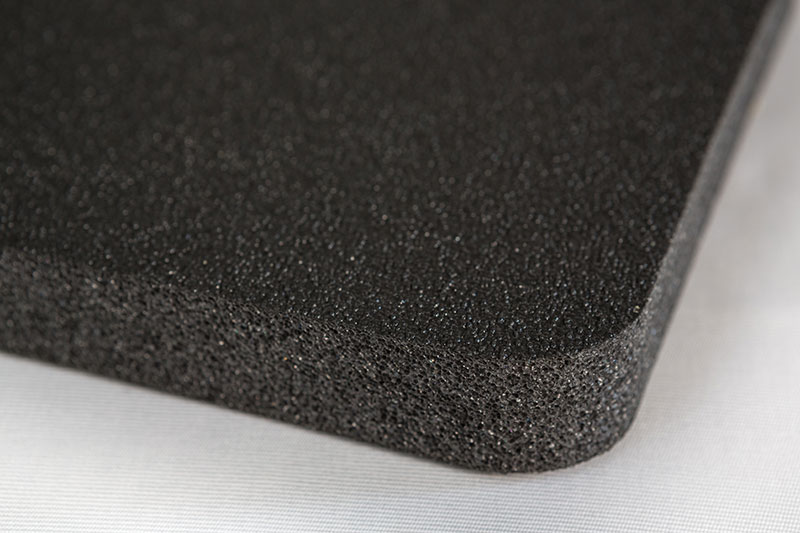

TR30

Closed cell chemical cross-linked polyethylene foam, excellent as a thermal insulator and for shock absorption, its grain makes it pleasant to the eye making it suitable not only for protective packaging but also for display packaging. It is floating, resistant to water and atmospheric agents.

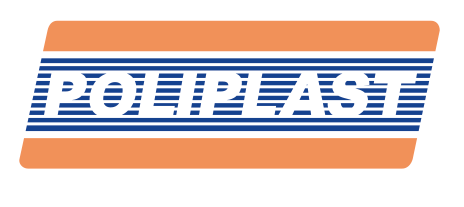

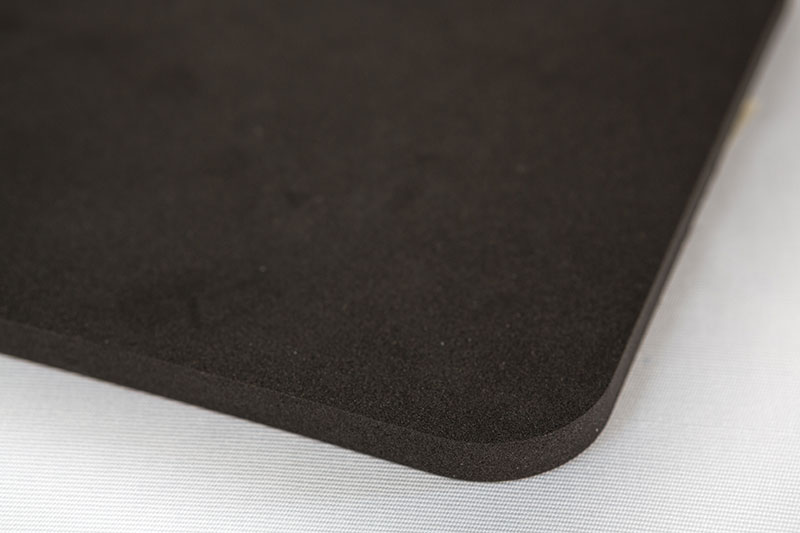

LD29-LD33

Closed cell polyethylene foam which has excellent uniformity in terms of density, cell size and color intensity (available colors: black, white, blue, yellow, red), these characteristics make it particularly suitable for the creation of display packaging and luxury items, presentation cases, samples, display stands and merchandising.

The resistance to water and chemical agents make it a very resistant material as well as pleasing to the eye, therefore it is suitable for making sports accessories and protections, and also for creating instrumentation trays for assembly lines.

Thanks to tests that certify its safety, it can also be used in the food sector as it is free of dangerous substances.

EVA

Copolymer of ethylene and vinyl acetate, resistant but elastic at the same time, make it particularly suitable for the production of sporting goods, such as accessories for swimming pools, mats and mattresses for gyms. Also suitable for the boating sector to make padding but also buoys and floats. The extremely compact cellular grain and the velvety finish makes it suitable for making luxury boxes for cosmetics, perfumes, jewelry, design objects, etc.