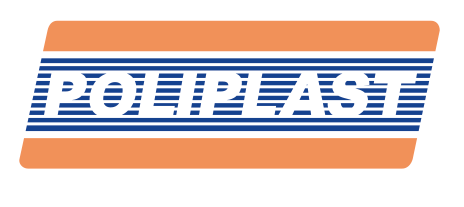

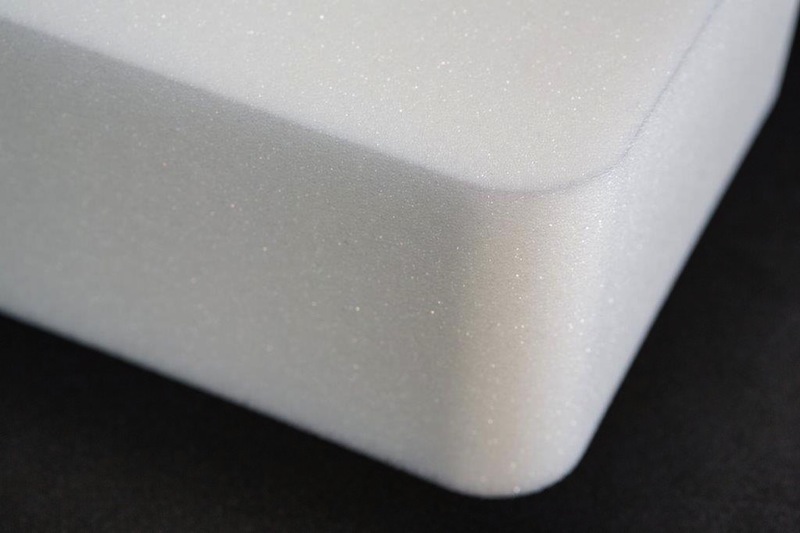

Foam flexible polyurethane

The FOAM FLEXIBLE POLYURETHANE (commonly known as “sponge” or “foam rubber”) is a synthetic material with cellular structure, that contain a high percentage of air in its volume.

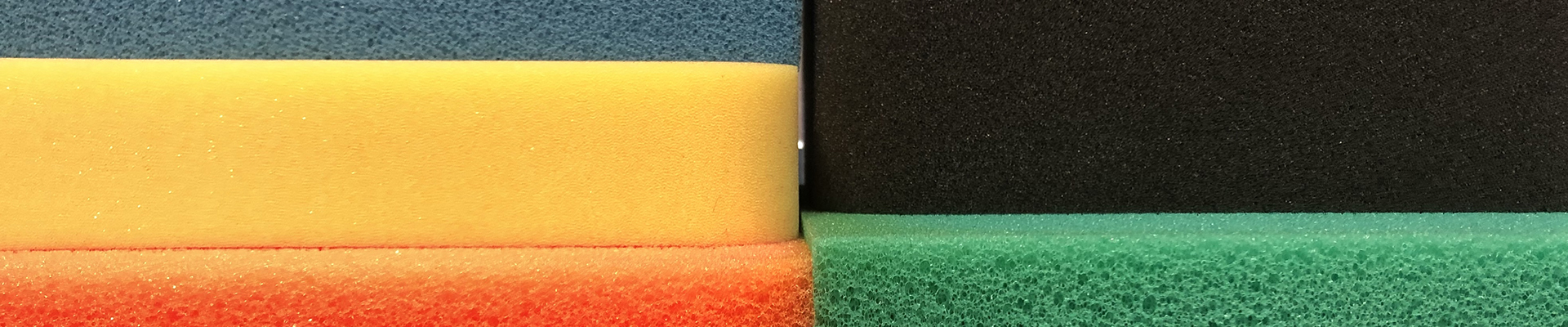

The polyurethane foams which can be polyether or polyester based arise from a chemical process called polymerization, i.e. from the blend between the isocyanate and the polyether or polyester polyol. Thanks to the adding of chemical products such as stabilizers, emulsifiers, catalysts, dyes, etc. the foam acquires very different characteristics in relation to density, softness, compression load deflection, tensile strength, ball rebound, etc. that contribute to define the final quality and the characteristics of the material. These components allow to obtain a wide range of polyurethane foams, all of them have open cell structure and good permeability to air and humidity, but different chemical characteristics that make them suitable for use in a variety of different areas: in the padding sector for its softness and elasticity, in packaging for its shock absorption capacity, in thermal and acoustic insulation for the good sound absorption values at medium and high frequencies, etc.

For particular uses there are also polyurethane foams:

- antistatic used for the packaging of electronic boards as they prevent the accumulation of electrostatic charges;

- self-extinguishing, obtained thanks to the addition of additives that give the foams a high flame resistance and a low level of smoke opacity and toxicity, specifically studied for use in public environments (hospitals, prisons, hotels, etc.) and to overcome the main national and international regulations.

Thanks to its ductility, polyurethane foam can be subjected to various processes, can be cut into smooth, ashlar and pyramidal sheets, can be die-cut, shaped to design, milled, excavated and also a adhesivizied and / or bonded to fabrics or other materials.